Manufacturing

Own brand:KING NEWTON

King Newton is a manufacturer specializing in the production of permanent magnet servo motors with complete specifications. From components to finished products, all have been passed strict quality control and standard inspections, and the performance is well received by our customers. At the same time, we actively invest in the development and production of hydraulic products, there are currently a number of mature products that can be widely used in industrial fields. King Newton is the only capable manufacturer in Taiwan of making permanent magnet servo motors.

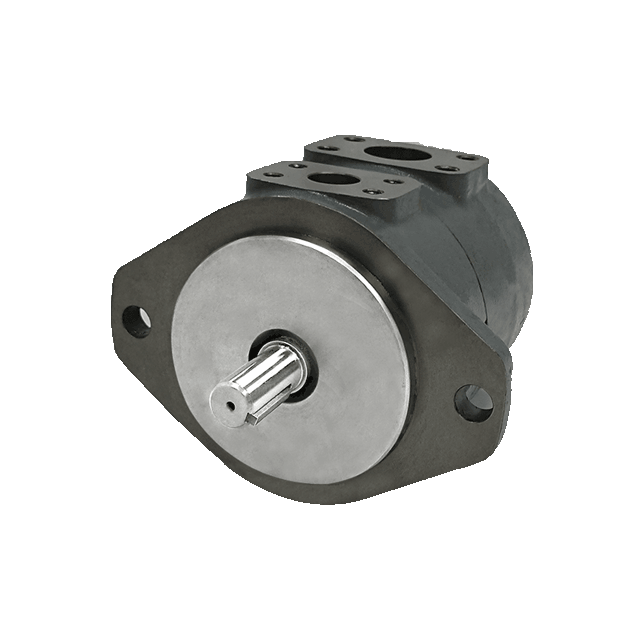

1.Hydraulic Vane Pump (SKP Series):

This SKP Vane Pump has been developed by TOKYO KEIKI from Japan with over 30 years of experience. The casting, processing, testing, and assembly of all components are done in Taiwan. It is a low noise, high pressure, high performance complex master & auxiliary vane pump, suitable for plastic machinery, die-casting machinery, machine tools, and construction machinery. Main Features:

a. Increased pulsation attenuation design (less shaking of the motor), which has greatly reduced the pulsation from pressure, thus lowering the noise and having more consistent sound.

b. Uses a reinforced outer shell which increases the strength and vibration/shock resistance. This also gives better noise reduction.

c. This (SKP) product series contains a wide range of outputs. It can be adjusted according to the system’s requirements, using double pumps with low and high pressure, small and large output designs to optimise energy savings.

d. Cartridge design which greatly decreases repair/maintenance difficulty.

2.Orbit Motor (IAOM Series):

Orbital Motors refers to an internal cycloidal gear, small sized, low speed, high torque hydraulic motor. Due to its simple structure, it has very good low speed capabilities with very strong short-term overload capabilities and a plethora of other advantages.

King Newton, and Danfoss, EATON’s orbital motors have interchangeable axels and joint faces which makes maintenance and part replacement convenient. Orbital Motors are currently being used widely across many different industries such as manufacturing, injection moulding, machine tools, construction machinery, and fishing.

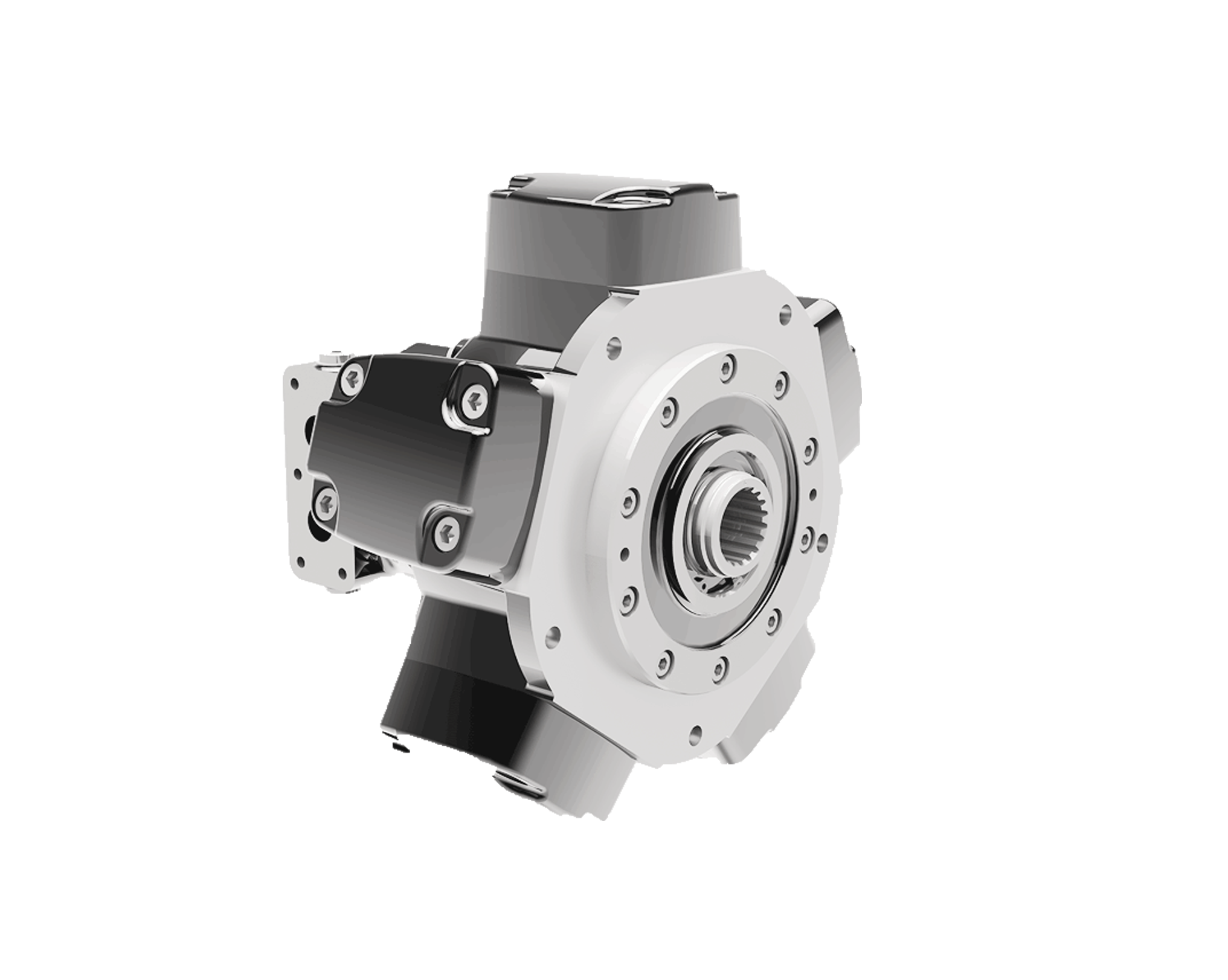

3.Hydraulic Motors (KAM Series):

From casting, processing, quality inspections, to assembly, and testing, our KAM Motors are 100% made in Taiwan. King Newton is the only supplier in Taiwan that can manufacturer high quality hydraulic motors and was also nominated for the “2019 Taiwan Excellence awards".

In Taiwan’s domestic hydraulic motor market, around 60% products from mainland China, with the other 40% coming from countries such as Italy, Japan, and Britain. The products from Mainland China usually have poor performance, inconsistent quality. Imported products are expensive which affects export competitiveness. King Newton’s goal is to provide for our customers with Taiwan manufactured hydraulic motors which balance performance and price. Currently worldwide there are around 10 well known manufacturers of hydraulic motors. The specifications for their products are not standardised and thus their parts cannot be shared. King Newton’s hydraulic motors are adaptor friendly, which means you can use other brand(s) (parts). This solves the problem of our customer’s manufacturing cost increases, and other issues resulting from the lack of function compatibility.

KAM series performance is comparable to products imported from Europe, with a 25-30% lower price (depending on the specifications). It is definitely the best value for money product. Below are the main characteristics:

a.High start-up torque, with stable low speed performance.

b.Uses a 5 piston eccentric axel, generating low noise.

c.Plane oil distribution plate design, high reliability, low internal leakage; piston cylinder and cylinder liner use sealing ring, so it has high volumetric efficiency.

d.Roller support is designed between crank axel and connecting bar foot, which has high mechanical efficiency.

e.Adjusting the plane oil distribution plate can be done by changing the direction of motor direction.

f.Made in Taiwan.

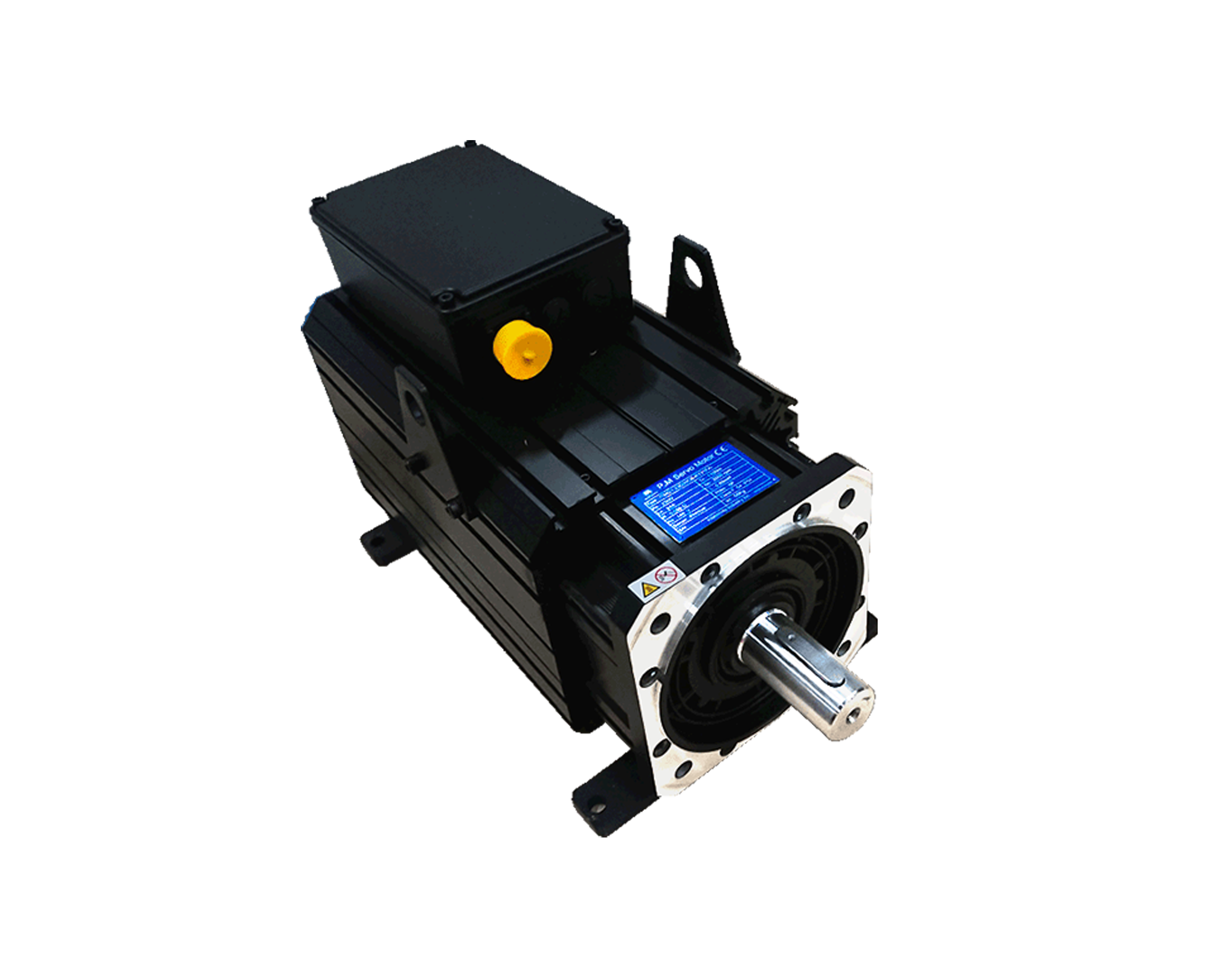

4.Permanent Magnet Servo Motors (ITMG Series):

a. Made in Taiwan.

b. Magnet mounting type motor, optional with various drivers.

c. Easy maintenance and long usage life.

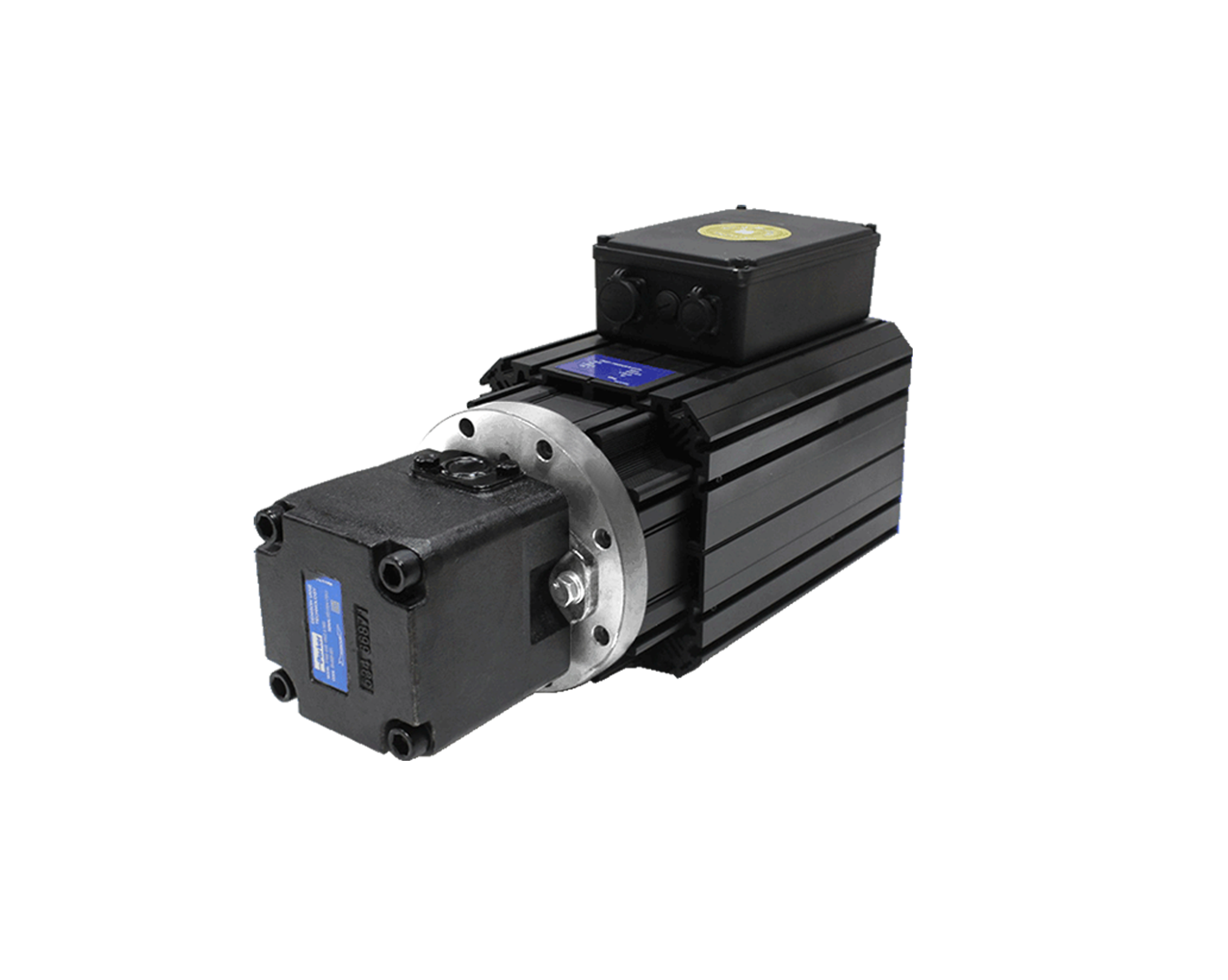

5.Servo Motor-Pump (KSMP Series):

a.Direct drive system can provide fast response and match high accuracy requirements.

b.The straightness of the shaft center is accurate, and the accuracy will not be lost due to repairing the pump or replacing parts, which can extend the usage life and increase the mechanical efficiency.

c.Using vane pump as configuration, it is very simple to replace the pump, only needs to disassemble the four screws that fix the case and remove it.

d.The appearance is concise and saving space, easily to design and to install for the whole machine.

Selling Agents

European well-known hydraulic brands

1.Parker Denison T7:

a.Specific designed for energy-saving servo system, it can maintain low noise, low internal leakage and high efficiency under the use of high pressure and high speed; in the other hand, the pressure level can maintain smooth and no jitter at the use of high pressure and low speed condition.

b.With double-vane design, it can achieve instant reversal very smoothly while conducting the pressure control.

c.The high speed would cause instantaneous suction of oil in a great amount, therefore the design of the oil inlet is relatively large. While speeding up, no vacuum will be generated and the sound of the operation will be kept low and steady.

d.The pressure can be increased up to 275 bar, and the speed can reach 3000 rpm, which is very suitable for energy-saving servo systems.

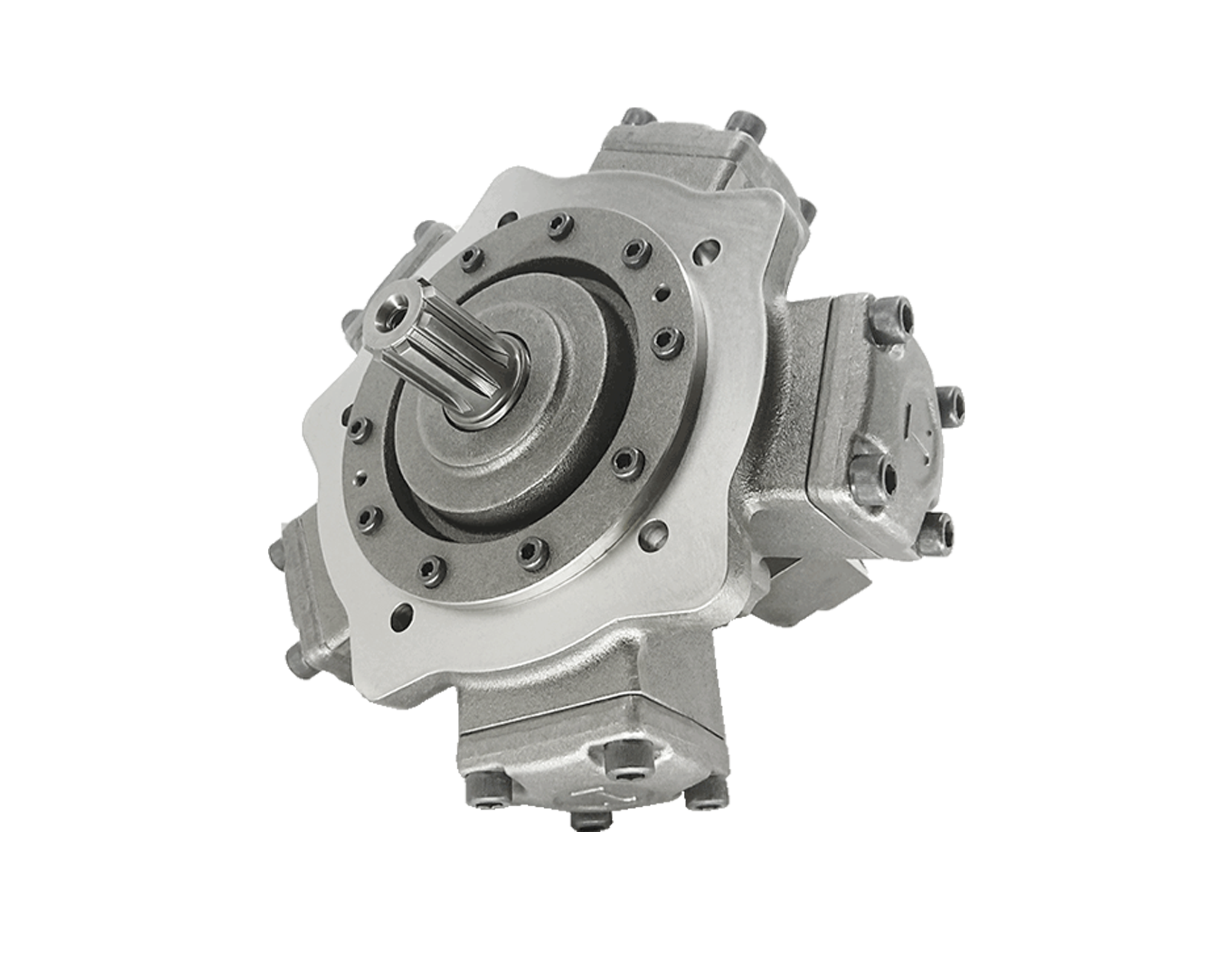

3.Parker Calzoni Hydraullic motor:

a.Excellent performance of MR-MRE series have been widely known.

b.It is transmitted to the rotating shaft through pressurizing the hydraulic cylinder insted of a common piston and connecting rod, the efficiency is better therefor.

c.Special materials and optimized design minimize friction and leakage.

d.The piston of the hydraulic cylinder has no lateral component of thrust, cause there is no additional abrasion on the moving parts.

e.There is no side force on the cylinder joint, the static balance of the motor shaft and the durability of the bearing are better.

4.intermot Hydraulic motor:

a.Large starting torque, stable, performance at low speed.

b.Using five-piston and eccentric shaft structure with low operating noise.

c.The flat oil distributor design has high reliability and low internal leakage; the piston cylinder and the cylinder liner use sealing rings, so it has high volumetric efficiency.

d.The between crankshaft and connecting rod seat is roller support, which has high mechanical efficiency.

e.Adjust the oil distributor can change the direction of motor rotation.

f.Complete specifications and displacement.

5.SAI Hydraulic motor:

a.GM series have high mechanical efficiency and high starting torque(mechanical efficiency is above 0.92 when starting).

b.The flat oil distributor is simple and reliable, which improves the sealing performance, therefore, the GM series have good stability at low speed, and can run smoothly under 1 r/min working conditions.

c.Volumetric efficiency can reach above 0.97.

d.Structural optimization reduces friction loss.

e.The piston and the bearing caes are firmly attached by the snap ring and with no gap in between. The motor can be operated in pump mode. When the oil inlet is closed, the motor can also run at high speed in freesheel mode.